Last month the Department for Transport published their first Freight Carbon Review. The review brings together evidence and opportunities for and barriers to reducing emissions caused by road freight. It identifies a number of government and industry led emission reduction initiatives and outlines what the government will put in place to support the industry in tackling the task of reducing greenhouse gas (GHG) emissions.

The 2008 Climate Change Act sets out the UK’s target to reduce GHG by at least 80% by 2050 (in relation to 1990 levels).

Alongside these targets the Government are also committed to improving air quality. The 2008 Ambient Air Quality Directive sets out strict limits for concentrations of major pollutants that impact public health which include nitrogen dioxide and particulate matter.

HGVs are estimated to account for around 16% of UK transport GHG emissions and around 21% of road freight nitrogen dioxide emissions.

The review will inform the Government’s ‘Emissions Reduction Plan’, which will set out how it intends to reduce GHG emissions through the 2020s. It will also support the development of further measures on air quality under the forthcoming ‘Air Quality Plan’.

As part of the review ‘industry collaboration’ was highlighted as an effective way to reduce the number of empty HGVs on the road, therefore reducing GHG emissions.

HGVs (above 3.5 tonnes) are currently estimated to account for around 16% of UK GHG missions from domestic transport, despite making up just 5% of vehicle miles

The study defined ‘collaboration’ within the context of the road freight sector as a joint initiative enabling operators to work more closely together in order to reduce the number of HGVs on the road and therefore decrease GHG emissions. Transport Research Laboratory (TRL) noted that this collaboration can be used to reduce empty running by identifying routes and journeys where operators can consolidate loads into single vehicle trips.

Examples of collaboration are described below:

Route scheduling and planning to create more efficient supply chains

Organisations that undertake logistics will do some form of route scheduling and planning as part of their supply chain operation. The effectiveness of this process varies between operators and there may be opportunities to optimise supply chain planning through collaborating with other parts of the business’s wider supply chain - for example by working vertically with suppliers and customers to optimise order cycles and delivery schedules.

Backhauling to reduce empty running

Operators can reduce empty running by backhauling (returning from a delivery with a new load). An extension of this is ‘forward hauling’, which makes use of available capacity en route to pick up loads on vehicles that would otherwise be running empty. Back and forward hauling are a means of filling completely empty loads or increasing loads for vehicles that would otherwise be running under capacity. This can be arranged between organisations independently, or through the use of a third party freight exchange.

Freight exchange

A freight exchange is an online service for haulage companies, logistics providers, freight forwarders and transport companies. It allows participants to search a database of available loads awaiting delivery and to advertise their available vehicle capacity. Such systems provide a platform that allows carriers to communicate freight traffic information to fellow operators. Online systems are usually subscription-based with a small charge for advertising and searching.

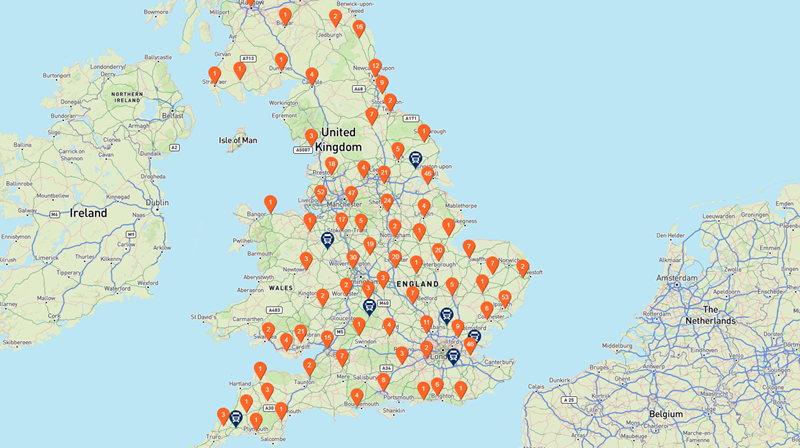

Screenshot of loads available on a freight exchange platform

Consolidation centres

Consolidation centres are logistics facilities from which consolidated deliveries are dispatched. These facilities enable companies to group loads together and allow goods to be delivered on appropriate vehicles with a high level of load utilisation, thereby reducing the number of delivery vehicles in operation.

Delivery and servicing plans

Delivery and servicing plans (DSPs) are designed to reduce the number of HGV trips generated by a premises or wider areas of multiple premises. DSPs are based on the principles of best practice in procurement - ensuring that goods are ordered within a single organisation and potentially across multiple organisations in partnership, to reduce the total number of trips generated to serve those premises.

The study included three case studies on industry collaboration which outlined below:

Returnloads.net was founded in 2000. Initially the site was set up as a noticeboard to help haulage companies around the UK advertise their excess loads and find return loads for their empty vehicles. In 2006, with the advent of new technologies, Returnloads.net became a fully functioning online freight exchange. This included developing an intelligent load and vehicle matching system, which automatically alerts members to available loads and vehicles that match their requirements. With ongoing development, Returnloads.net has continued to grow - with over 90,000 available haulage loads posted on the platform every month. It now has over 1,500 users from across the UK including owner drivers, freight forwarders and a number of the country’s largest haulage firms. In 2016 loads totalling over 16.5 million miles were covered on the platform resulting in a potential saving of 25,514 tonnes of CO2.

Discussions between two manufacturers with compatible products identified that both were receiving less than full load orders for some smaller customers, and were unable to optimise these deliveries due to geographical delivery areas. Both companies wanted to improve the efficiency of these deliveries. Analysis showed commonality of delivery locations and compatible order profiles, and identified that significant reductions in empty km could be achieved through consolidation of these deliveries, including through the appointment of a third party logistics company. Whilst not quantified, the operators reported savings in vehicle km and reduced transport costs.

Sainsbury’s has been working with third party logistics provider NFT for over 15 years in both primary and secondary distribution. NFT approached Sainsbury’s with a proposal to collect and consolidate suppliers’ products through one of three transhipment hubs strategically located within the UK. This enabled a reduction in inbound regional distribution centre (RDC) deliveries by optimising vehicle fill on each load as well as utilising the same vehicles to collect suppliers’ products en route following an RDC delivery. Over 240 manufacturers across 120 collection points were involved in this process and, as a result, average vehicle fill has increased by 20% during that time, therefore reducing empty running substantially. By utilising Sainsbury’s secondary store fleet to undertake primary collections and deliveries, which now account for 26% of all journeys, this initiative has further reduced Sainsbury’s carbon footprint. 5.4 million km have been saved per annum, equivalent to 4.6 million kilograms of CO2. Using some of the primary NFT fleet to undertake store deliveries has further reduced km and CO2 emissions (2.2 million km, equivalent to 1.9 million kg of CO2)

Industry Collaboration

The TRL study notes that measuring the benefits of collaboration is challenging, not least due to issues around the availability of data. One key challenge is that collaboration takes a number of different forms and identifying the benefits from specific individual actions can be difficult. However, available data on empty running and vehicle utilisation indicate the size of the opportunity for backhauling.

SRF, for example, note that there has been an upward trend in empty running of vehicles, and that the proportion of HGV km running empty increased from 27% in 2004 to 29% in 2013. They suggest that the road freight industry could save £160 million in fuel a year and avoid 426,000 tonnes of GHG emissions, if it were able to reduce the empty running of vehicles to the lowest levels recorded at 27.2% for rigid and 25.2% for articulated trucks.

Further work is needed to understand the costs and benefits of available measures to improve industry collaboration. As an outcome of the Freight Carbon Review and building on the findings of the TRL study, DfT will consider options for addressing these evidence gaps and overcoming the barriers to wider industry collaboration.